What is EDI Integration and How Does it Work

What is EDI?

EDI (Electronic Data Interchange) is the exchange of B2B data between two trading parties using a standard electronic format over the Internet. Businesses can efficiently exchange data using EDI systems as it completely eliminates paper-based documents and reduces human operations.

Every EDI has a standardized document format, and each document has its own business purpose. The trading parties can agree to a set of documents that they will exchange via EDI. Every organization switches to EDI as they upscale, and the need arises to move a large number of orders frequently through their supply chain and b2b networks.

What is EDI integration?

EDI integration is the process of establishing the EDI channel between two trading partners that will allow the exchange of EDI documents. It is also the process by which an organization integrates EDI data with its ERP software.

Integrating EDI into business systems requires the expertise of EDI developers or vendors who will set up EDI connections with your trading partners. Once the integration is complete, you can send and receive EDI files such as invoices, purchase orders, shipment notices, warehouse and inventory updates, etc.

Process of EDI integration

There are five steps in the process of EDI integration. Let’s take a look.

Understanding EDIs in the workflow

The first step in EDI integration is scoping out the workflow. Let’s say there’s an 850(EDI for purchase order) and 810(EDI for invoice) in scope for a product that needs to be shipped from the vendor to the buyer. The buyer will send 850 to place the order. In return, the vendor or trading partner will send 810 confirming the order and asking the buyer to make the payment (Note: 850 always precedes 810 because an invoice can only be generated after an order is placed).

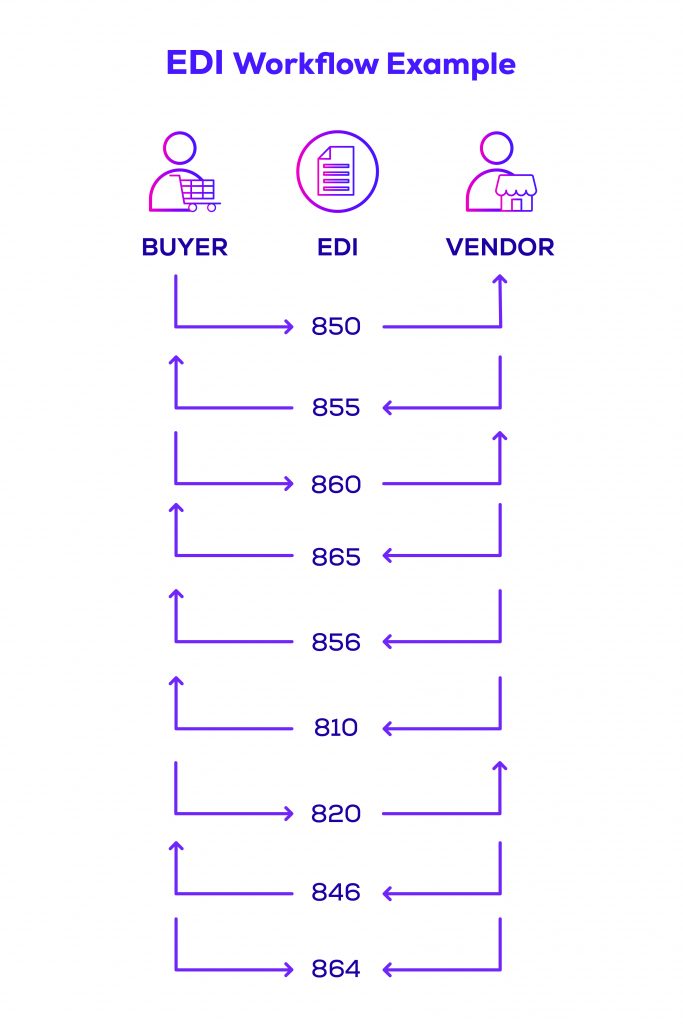

Below is an example of one such EDI workflow.

EDIs in the workflow:

| EDIs | Document Type | Purpose |

| 850 | Purchase order | Sent to the vendor by the buyer requesting goods and services |

| 855 | Purchase order acknowledgment | Sent to the buyer by the vendor upon confirmation, update, or rejection of the purchase order |

| 860 | Purchase order change request | Sent to the vendor if the buyer needs to make changes to the original purchase order |

| 865 | Purchase order change acknowledgment | Sent to the buyer as a response to the changes requested in the original purchase order |

| 856 | Advance shipment notice | Sent to the buyer by the vendor, giving them details about the shipment |

| 810 | Invoice | Sent to the buyer by the vendor indicating the payments due and requests to pay under agreed terms |

| 820 | Remittance advice/Payment order | Exchanged between the buyer and vendor to discuss the details of the payment |

| 846 | Inventory enquiry specification | Used by both buyers and sellers to update the details of the inventory |

| 864 | Text message | Used by both buyers and vendors to communicate in free text |

Hence first, it is important for you to understand

- Who are the trading parties involved?

- What are the EDI document types in scope?

- What will be the sequence of EDIs in scope?

EDI specification gathering

An EDI specification will have a format design with certain syntax and semantics managed by you or your partner. Simply put, it has the list of data points to be exchanged with your trading partner, their data type (string, number, etc.), and which data point is mandatory or optional. Generally, the bigger business (ex., Walmart) decides the spec because they have to manage thousands of vendor relationships. It is more sensible for such a business to create a common EDI spec that all its partners (with one or two other partners) can follow. However, it is also allowed to customize any EDI document specification if both parties agree.

EDI specification configuration

Once you know the specs of the EDIs in scope, you can set them up on the EDI platform. Usually, the developer can use this information and configure it on the EDI platform or software. This lets your EDI software parse (or understand) the EDI files that you exchange with your trading partners. It also lets your system know what data fields to expect in an EDI file. Let’s consider an example. Suppose your EDI specification dictates the Purchase Order # is mandatory on an 850 Purchase Order EDI file when it’s missing in an 850 EDI file sent by your partner. In that case, your EDI software will throw an exception or a warning.

EDI mapping

EDI mapping is the process of defining sources in your EDI file to the corresponding destination fields in your ERP. It could be the other way around too. For example, N3 (Address) segment’s information is mapped to the address table/field in your ERP system. While doing so, the developer may perform transformations. Let’s say you might also want to store everything in upper case. This process of taking the data from a source, transforming it, and storing it in the destination is called EDI mapping. Typically, your EDI software/platform allows you to perform the mapping. You can do it manually by coding, using EDI software with ERL features, or using other ETL tools with your EDI system.

EDI integration and development

The final step is to deploy the EDI specifications configured and the mapping information as a process. So whenever an EDI file arrives from your trading partner, two things happen. (1) The EDI file gets parsed using the EDI specification configuration. This is where your EDI software typically catches data errors. For example, the software throws errors or alerts when a required data field is missing. (2) If the EDI data is clean, the EDI software invokes the mapping definitions and stores the data inside your ERP. This automates your EDI workflow.

Challenges in EDI integration

The EDI industry is slowly being taken over by newer technologies like faster and easier APIs that are revolutionizing the future of EDI integrations. Yet many organizations today are bound to face challenges in EDI integrations for several reasons. Let’s find out why.

EDI integrations are still complex

Integrating EDI is still difficult. Processes like mapping, understanding specs, and ERP integrations can’t always be flawless. EDI structures can get complex to understand and maintain in production. For example, a mandatory field that does not pre-exist in the spec configuration can take time to integrate. It can even violate the EDI if not done properly.

Legacy EDI services

Legacy EDI services are filled with limitations, such as poor communication between EDI service providers and customers, rigid configuration environments, and outdated methods. A lack of modern solutions can impact the supply chain that needs to keep up with the fast-growing market. Yet, many organizations still rely on legacy EDI services, forcing new businesses to comply with the same traditional methods.

The EDI developer pool is depleting

The EDI developer pool is shrinking due to many reasons. EDI has a steep learning curve, and there aren’t many EDI developers around since it’s a legacy technology. In the near future, the population of EDI developers will become scarce, and organizations with in-house EDI systems may feel its effect during resourcing.

Conclusion

EDIs are generally hard to develop and maintain in a production environment. And to add to that problem, most modern-day developers are not familiar with EDI. Due to this, the EDI industry is seeing a shift towards EDI-as-API platforms, especially among small businesses. These are API-based EDI software solutions that let you send and receive EDI using API. When you are using an API, you don’t have to spend time learning the complexities of EDI, which includes learning about semantic rules, syntax rules, and other terminologies.

Zenbridge is one such platform that uses modern API integrations, which makes it easy for modern developers to build EDIs without having to go through the complex learning stages. To learn more about Zenbridge and its EDI integration process, you can schedule a demo with a developer by clicking here.